Our Products Flanges

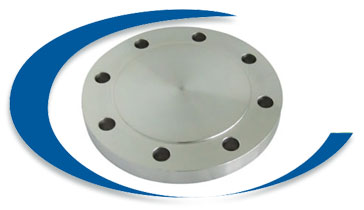

What is Blind Flange?

We are a trusted firm engaged in offering a wide assortment of Blinds Flanges. Demanded extensively for the purpose of constructing bus bodies, shutters and grills, these products are manufactured using optimum quality raw material, obtained from authentic vendors of the industry. In addition to this, we make sure to examine the quality of the entire range before delivering these products to the clients end.

Commonly referred as blanking flanges, Blind pipe flanges are widely used in high pressure applications. Blind flanges are generally used to seal the end of a piping system to prevent flow of liquids or gases. The use of blind flanges allows ease of access to a piping system once it has been closed.Our blind flanges are available with raised or RTJ faces and also with female threads. Blind flanges can be supplied with or without hub as per the customer requirements.We are an ISO 9001:2008,ISO 9001-2008, ISO 14001-2004, OHSAS 18001-2007, NSIC-CRISIL, EEPC, and QA-UKAS (ISO 9001-2008), SSI Certified company that follows total Quality Management System. and have been recognized as one of the world’s leading stockists and manufacturer of quality metals for over two decades and are committed to quick responses, unsurpassed quality, competitive pricing, reliable deliveries and an exhaustive inventory.

What is Lap Joint Flange?

Lap Joint Pipe Flanges slide over the pipe and are most commonly used with Stub End Fittings. A pipe is typically welded to the Stub End and the Lap Joint pipe flange is free to rotate around the stub end. The benefit of this is that there will not be any issues with bolt hole alignment. Lap Joint pipe flanges are often used for applications that require frequent dismantling. Slip on Pipe flanges with a hub has published specifications that range from 1/2" thru 24". Sizes above 24" are produced as lap joints to slip on dimensions. Coastal Flange provides Lap Joint pipe flanges in all material grades, specifications and sizes.

Lap Joint Flanges are similar to other types of industrial flanges, but it does not have a raised face. Lap joint flanges are used in conjunction with a “Lap Joint Stub End”. The total initial cost of a lap joint flange along with a stub end is around one-third higher than that of comparable welding neck flanges. The pressure holding capacity of lap joint flanges is comparatively lower, and the fatigue life for the assembly is only one tenth that of welding neck flanges.

What is Weld neck Flanges?

Weld neck pipe flanges are connected to the pipe by welding the pipe to the neck of the pipe flange, which helps to pass on the stress from the weld neck to the pipe itself. This also reduces high stress concentration at the base of the hub of the weld neck pipe flanges. Weld neck pipe flanges are generally used in high pressure applications, where hot or cold temperatures exist. The inside diameter of a weld neck pipe flange is machined to match the inside diameter of the pipe.

-

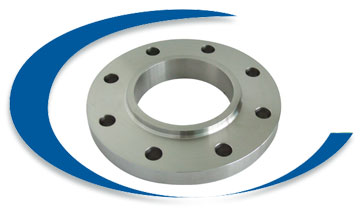

What is Slip-on Flange?

Slip-on pipe flange usually slips over the pipe. Slip-on pipe flanges are typically made with an inside diameter of the pipe flange slightly larger than the outside diameter of the pipe. This allows the slip-on flange to slip over the pipe. Slip-on pipe flanges are welded (usually both inside and outside) to provide strength and prevent leakage. Slip-on pipe flanges can sometimes also have a boss/ring or hub, and can be made with a bore to suit either pipe or tube. Ring pipe flanges and hub pipe flanges are both considered slip-on pipe flanges because they both slip over the pipe.

Slip-on flanges are generally preferred by users over weld neck flanges, as they are a cheaper option than weld neck flange and the fact that less accuracy is required when cutting pipe to length.Slip-on flanges are available with raised, flat or RTJ faces, and are also available in orifice configurations.We offer slip-on pipe flanges manufactured at our facility to companies in various industries including shipbuilding, power generation, petrochemical plants, oil refineries, waste water treatment plants, paper mills, pharmaceutical plants and turnkey projects among others.

What is Socket weld Flange?

Socket weld flange is similar to the slip-on flange in outline, but the bore is counter-bored to accept pipe. Socket welding pipe flanges are typically used on smaller sizes of high pressure pipes. Socket weld flanges are widely used in high pressure systems such as hydraulic equipment and steam lines. Socket weld pipe flanges are attached by inserting the pipe into the socket end and then applying fillet weld around the hub of the flange. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. An optional internal weld may be applied in high stress applications.

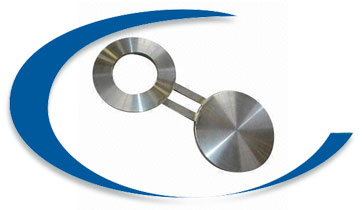

What is Spectacle Blind Flange?

Separating one part of a line from another requires a spectacle blind, able to switch from closed to open and back again. Bleed rings provide a means to release pressure from the pipe through a controlled opening. Spectacle flanges are known for their tensile strength, dimensional accuracy and durability. These flanges are made by using best quality material. We offers an extensive range of spectacle flanges in various dimensions and specification.The first and most widely used type are spec blinds – short for spectacle: these are flanges with two equal outside diameter (OD) parts welded together by way of a ‘bridge’.

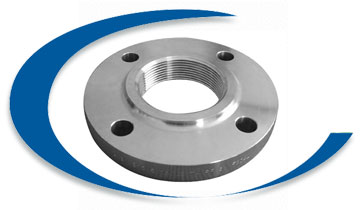

What is Threaded Flange?

We offer carbon steel, stainless steel, alloy steel and special steels as per drawings or customer specifications, specially used in the oil & gas, petrochemical and processing industries.All kinds of stainless steel Threaded flanges are easily purchased under single roof named as Spire Industrial Equipments Co. Our stainless steel flanges are 100% free from any corrosion attack assuring their longevity. In addition ton this, our stainless steel flanges are universally appreciated for their high level of strength. We have a team of trained technocrats having immense experience in bringing superior quality stainless steel plate flanges.